The dental industry is undergoing one of its most exciting transformations in decades, and at the heart of this shift lies 3D printing technology. Once considered experimental, dental 3D printing has rapidly evolved into a mainstream manufacturing approach that is redefining how dental labs, clinics, and manufacturers design, produce, and deliver dental solutions. From crowns and bridges to aligners and surgical guides, 3D printing is bringing speed, precision, and personalization to modern dentistry.

A Market on a Powerful Growth Trajectory

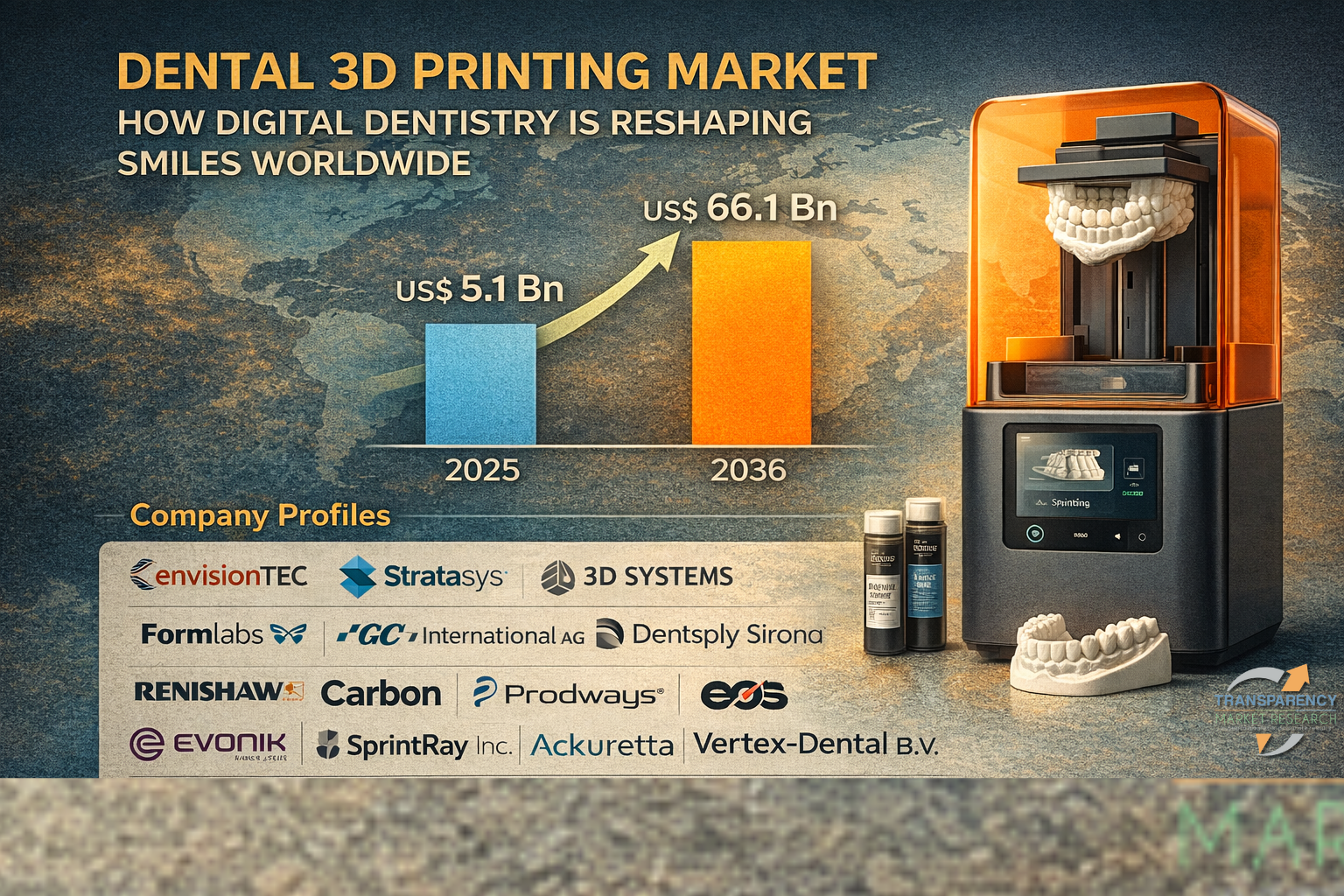

The global dental 3D printing market was valued at US$ 5.1 Billion in 2025 and is expected to surge to US$ 66.1 Billion by 2036, expanding at an impressive CAGR of 26.3% from 2026 to 2036. This exponential growth reflects a clear industry shift toward digital workflows and patient-specific dental care.

What’s fueling this momentum? The answer lies in a perfect convergence of technology adoption, rising patient expectations, and operational efficiency. Dental professionals today are under pressure to deliver faster turnaround times without compromising quality—something traditional manufacturing methods often struggle to achieve. Dental 3D printing addresses this challenge head-on.

Why Customized Dental Solutions Are Driving Demand

Customization has become a defining trend in healthcare, and dentistry is no exception. Every patient’s anatomy is unique, making mass-produced dental components less effective in many cases. Dental 3D printing allows practitioners to create highly customized prosthetics, orthodontic appliances, dentures, and implants, tailored precisely to individual patient needs.

This level of personalization not only improves clinical outcomes but also enhances patient comfort and satisfaction. Digital impressions combined with 3D printing eliminate errors associated with manual molds, reduce material waste, and ensure a superior fit—making it a win-win for both dentists and patients.

The Role of CAD/CAM Integration in Market Expansion

Another major growth catalyst is the increasing integration of CAD/CAM (Computer-Aided Design and Computer-Aided Manufacturing) systems into dental practices and laboratories. These systems seamlessly connect digital scanning, design, and 3D printing into a unified workflow.

With CAD/CAM integration, dental professionals can move from scanning to final production in a matter of hours rather than days. This not only accelerates treatment timelines but also lowers operational costs and minimizes dependency on external dental labs. As digital dentistry becomes more accessible, adoption of dental 3D printers is accelerating across both developed and emerging markets.

Expanding Applications Across Dental Specialties

The scope of dental 3D printing continues to broaden. Today, it is widely used in:

- Prosthodontics for crowns, bridges, and dentures

- Orthodontics for clear aligners and retainers

- Implantology for surgical guides and implant components

- Restorative dentistry for models and temporary restorations

As material science advances, printable dental resins and metals are becoming stronger, more biocompatible, and aesthetically superior—opening new possibilities for long-term restorations and complex procedures.

Competitive Landscape: Innovation at the Core

The dental 3D printing market is characterized by intense innovation and a growing number of technology providers. Leading players are investing heavily in printer accuracy, speed, material compatibility, and user-friendly software to gain a competitive edge.

Key companies shaping the global dental 3D printing ecosystem include EnvisionTEC, Stratasys Ltd., 3D Systems, Formlabs, GC International AG, Dentsply Sirona, Renishaw, Ultimaker, Carbon, Prodways Group, EOS GmbH, Evonik, SprintRay, Ackuretta, Vertex-Dental, Proto3000 Dental, LuxCreo, and several others. These players are focusing on strategic partnerships, product launches, and material innovations to expand their global footprint.

What Lies Ahead for Dental 3D Printing?

Looking ahead to 2036, the dental 3D printing market is expected to become an integral part of routine dental care. As costs decline and technology becomes more user-friendly, even small and mid-sized dental clinics are likely to adopt in-house 3D printing capabilities.

Emerging trends such as AI-assisted design, cloud-based dental workflows, and sustainable printing materials are expected to further enhance efficiency and adoption. For manufacturers, investors, and dental professionals alike, the market presents substantial opportunities for growth and innovation.

Final Thoughts

The dental 3D printing market is no longer just about technology—it’s about transforming patient experiences and redefining dental care delivery. With strong growth projections, expanding applications, and continuous innovation, dental 3D printing is set to become the backbone of next-generation dentistry. As the industry embraces digital solutions, the future of dental care looks faster, smarter, and more personalized than ever before.