The global pharmaceutical and biotechnology industries are undergoing rapid transformation, driven by the growing demand for sterile drug manufacturing, biologics, and advanced therapies. At the core of this evolution lies the aseptic transfer system market, which plays a critical role in maintaining contamination-free material movement across controlled manufacturing environments. As regulatory scrutiny intensifies and manufacturers focus on quality assurance, aseptic transfer systems have emerged as an essential component in modern cleanroom and sterile production processes.

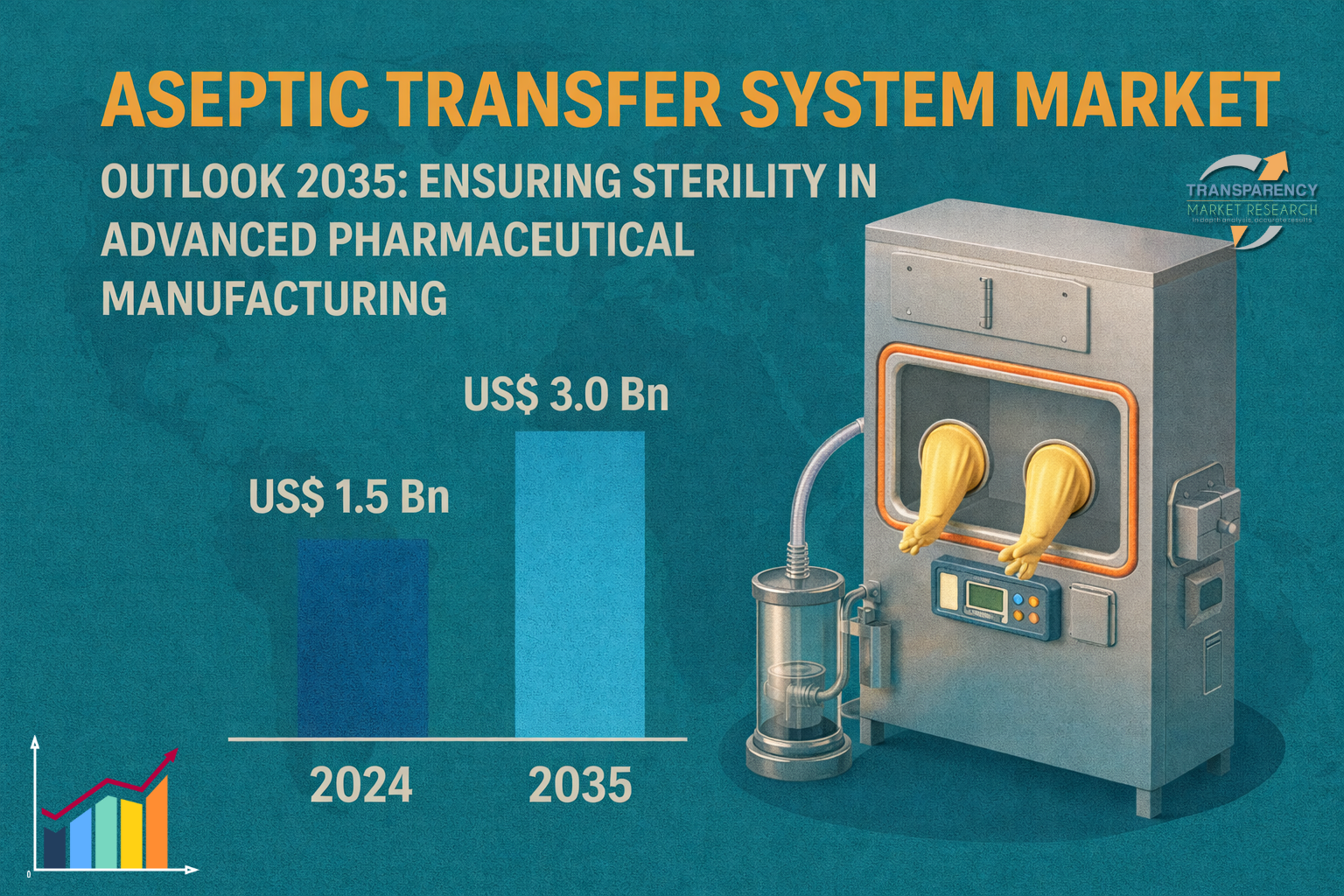

In 2024, the global aseptic transfer system market was valued at US$ 1.5 billion. With increasing adoption across pharmaceutical, biotechnology, and healthcare manufacturing facilities, the market is projected to reach US$ 3.0 billion by 2035, expanding at a compound annual growth rate (CAGR) of 6.7% from 2025 to 2035. This growth reflects the industry’s strong emphasis on product safety, regulatory compliance, and operational efficiency.

Market Growth Drivers

One of the primary drivers fueling market growth is the rising production of biologics, vaccines, and injectable drugs, which require strict aseptic conditions throughout the manufacturing lifecycle. Aseptic transfer systems enable the safe transfer of powders, liquids, and components between isolators, cleanrooms, and processing equipment without compromising sterility. As biologic pipelines expand globally, manufacturers are increasingly investing in validated aseptic technologies to meet stringent quality standards.

Another key growth factor is the tightening of regulatory requirements by global health authorities such as the U.S. FDA and the European Medicines Agency. Regulatory bodies mandate contamination control and traceability across pharmaceutical production environments, pushing manufacturers to adopt advanced aseptic solutions. Aseptic transfer systems help minimize human intervention, significantly reducing contamination risks and ensuring compliance with Good Manufacturing Practices (GMP).

The market is also benefiting from technological advancements, including rapid transfer ports (RTPs), single-use transfer systems, and automated aseptic solutions. These innovations enhance operational flexibility while reducing cleaning validation costs and downtime. The growing preference for single-use technologies, especially in biopharmaceutical manufacturing, is further accelerating demand for modern aseptic transfer systems.

Market Size & Highlights

The aseptic transfer system market reached US$ 1.5 billion in 2024 and is expected to double in value by 2035, reflecting consistent demand across multiple end-use industries. The market’s steady growth rate of 6.7% CAGR highlights its resilience and importance in sterile manufacturing operations.

Among system types, liquid transfer systems dominated the market in 2024, accounting for 61.4% of total revenue. Liquid transfer systems are widely used in vaccine production, injectable drugs, and biologics manufacturing, where precise, contamination-free fluid handling is critical. Their reliability, scalability, and compatibility with automated processes make them the preferred choice across pharmaceutical production lines.

Regional Insights

From a regional perspective, North America led the global aseptic transfer system market in 2024, holding a revenue share of 35.8%. The region’s dominance can be attributed to a well-established pharmaceutical industry, strong presence of biopharmaceutical manufacturers, and early adoption of advanced sterile technologies. Significant investments in biologics, cell and gene therapy, and vaccine manufacturing facilities continue to drive demand across the U.S. and Canada.

Europe follows closely, supported by stringent regulatory frameworks and expanding pharmaceutical production capacities. Meanwhile, the Asia Pacific region is expected to witness the fastest growth rate over the forecast period, driven by increasing pharmaceutical manufacturing activities, rising healthcare investments, and growing outsourcing of drug production to countries such as China and India.

Competitive Landscape and Key Players

The global aseptic transfer system market is moderately fragmented, with several established and emerging players focusing on innovation, customization, and regulatory compliance. ABC Transfer, Aseptic Group, Cape-Europe, Castus GmbH & Co. KG, and Central Research Laboratories are among the leading companies shaping the competitive landscape.

Other prominent players such as Sartorius AG, STERIS plc, EMA SINERGIE S.p.A., JCE Biotechnology, Pharmalab India Private Limited, and Steriline S.r.l. are expanding their product portfolios through advanced designs and strategic collaborations. These companies are investing in R&D to develop more flexible, automated, and single-use compatible aseptic transfer solutions to address evolving industry needs.

Strategic partnerships, facility expansions, and product launches are common approaches adopted by market players to strengthen their global footprint. Customization and system integration capabilities are increasingly becoming key differentiators in winning contracts from large pharmaceutical manufacturers.

Challenges and Opportunities

Despite strong growth prospects, the aseptic transfer system market faces challenges such as high initial investment costs, complex validation requirements, and integration issues with legacy systems. Smaller manufacturers may hesitate to adopt advanced systems due to budget constraints and technical complexities.

However, these challenges also create opportunities for innovation. The growing demand for modular, scalable, and cost-effective aseptic transfer solutions, along with increasing adoption of single-use technologies, presents significant growth potential. Additionally, expanding pharmaceutical manufacturing in emerging economies is expected to open new revenue streams for market participants.

Outlook Through 2035

Looking ahead, the aseptic transfer system market is poised for sustained expansion as sterile manufacturing becomes non-negotiable across pharmaceutical and biotechnology industries. With increasing regulatory oversight, growing biologics pipelines, and advancements in aseptic technologies, aseptic transfer systems will remain a cornerstone of contamination control strategies. Companies that prioritize innovation, compliance, and operational efficiency are well-positioned to capitalize on the market’s strong growth outlook through 2035.